Introduction

It is a very important and essential requisite for a denture base to resist fracture. Fractures can be prevented by improving the strength of the Polymethyl methacrylate. Various approaches for strengthening acrylic resin prosthesis have been suggested. Chemical modification has been performed to produce graft co-polymers or rubber methacrylate known as high impact resins[3]. Reinforcement has also been attempted through the incorporation of metal wires in fracture prone areas. Reinforcement of resins with various fibers like carbon fibres, polyaramide fibers, glass fibers and nylon fibers has also been studied[4]. Fibre reinforcement has been found to be more economical and esthetically acceptable mode of strengthening the denture base.

Polymethyl methacrylate is the most commonly used material in denture fabrication because of its ease of processing, favorable working characteristics, accurate fit, stability in oral environment, superior esthetics, use with inexpensive equipments and adequate mechanical properties[1]. Although this material is widely used as a main component of denture base polymer for many years, it gets fractured or sometimes gets cracked in use due to accidental dropping or from fatigue. This is often seen in maxillary complete dentures, where continual flexing of the denture base during function leads to crack development[2]. Sudden breakage of the denture is a situation that deprives the denture wearers of their dentures and is a source of great inconvenience.

Today the most acceptable fibers for dental polymer reinforcements are glass fibers because of their good aesthetics and better bonding with polymers[5]. They can also be easily adapted to the desired shape and length which is then suitable for incorporation into denture base polymer material. These fibres come in various forms, thickness and qualities. Glass fibres have porous prepolymer matrix and when pre-impregnated with monomer they show better bonding with PMMA. To strengthen dental polymers, glass fibers have been used in different forms such as woven, loose, and continuous such as roving or fibers bundles. Addition of glass fibers has shown to result in higher transverse strength, flexural modulus, fatigue strength and impact strength[6]. In this study four brands of heat cure resins were selected and their transverse strength was evaluated after glass fibre addition in different concentrations i.e. 1%, 2%, 5% and 10% by weight.

Materials And Method

Total two hundred test samples were prepared using four different brands of heat cure (Fig 1) denture base resins as shown in Table 1. Each group was further divided into five subgroups comprising of ten samples each depending upon the concentrations of glass fibres used (Fig 2) as shown in Table 2.

| Fig 1 : Heat Cure Denture Base Resins Used In The Study

|

| Fig 2 : Glass Fibres Used In The Study

|

| Table 1

|

| Table 2

|

The test was conducted in accordance with ADA specification no 12 / ISO: 1567-1981(ISO 6887-1986) for denture base polymers at room temperature.

Preparation Of The Mold

For standardization of specimens, a stainless steel die plate of dimension 60mm in length, 10mm in width and 4mm in thickness was fabricated as per ADA specification no. 12 for denture base resins. Dental stone was used for flasking purpose. Lower portion of dental flask was filled with freshly mixed dental stone. The stainless steel die plate was coated with petrolatum jelly and placed over this mixture. Upper portion of the flask was then positioned atop the lower portion of flask and a second mix of dental stone was poured and allowed to set for 30 minutes. Upon completion of the setting process, the flask was opened and metal die was carefully removed from the surface of the mold. Mold cavity was cleaned with boiling water. The mold cavity thus obtained was used for the preparation of acrylic resin samples.

Preparation of control group specimens- Control groups had no concentration of glass fibers. In this study, four different control groups were prepared as shown in Table 2. A mixture of polymer and monomer in the ratio of 3:1 by volume was measured and mixed in a porcelain jar. Acrylic dough was packed by compression molding technique. Finally the flasks were clamped and final closure was done under pressure. Heat cure resin was processed with short curing cycle (boiling at 740c approximately for 2 hours and then increasing the temperature of the water bath to 100oc and processed for 1 hour) and bench cooled for 30min. Cured acrylic resin plates were carefully removed from the mold. Acrylic resin plates were cut lengthwise into equal strips with the help of a fret saw. Stripes were finished to specific dimension of 60+_0.03 mm in length, 10+_ 0.03mm in width, and 4+_ 0.03mm in thickness and were marked at the end. Any specimen strip that did not fulfill these criteria was discarded.

All the control group specimens A0, B0, C0 and D0 containing ten specimens each were prepared in the same manner and finished.

Preparation of specimen with different concentrations of glass fibres : All brands of conventional heat cure denture base resins were first reinforced with 1% by weight glass fibres. For this 0.48 gm of glass fibres were weighed which amounts to 1% by weight of the total mixture. The measured quantity of glass fibres were immersed in a beaker with a predetermined volume of monomer liquid, then the required mass of powder was added to the mix and stirred so that the fibres were randomly oriented. After the material reached the dough stage, it was kneaded and packed into the mould. The specimens were trial packed, polymerized, recovered, cut into stripes, finished and polished as stated for the control group. Same technique was used with each brand of PMMA denture base resin materials by adding 1% by weight glass fibres to obtain the samples of A1, B1, C1 and D1 subgroups, with ten samples each.

Similarly for concentration of 2% by weight 0.96gm of glass fibres for 5% weight 2.4gm of glass fibres and for 10% weight 4.8gm glass fibres were incorporated into the mixture. Same procedures for packing, flasking, polymerization, curing, finishing and polishing were carried out and samples for all the subgroups were obtained. All the samples were stored in water for two weeks in their respective marked containers (Fig 3).

| Fig 3 : Samples Stored In Water

|

The specimens were mounted on Hounsfield universal testing machine (Fig 4). Each specimen was placed on the bending fixture consisting of two parallel supports 50mm apart, which represented the distance between the molars in complete maxillary denture. Load was applied at the centre of the specimen at a cross head speed of 0.5cm/min. Machine had a digital monitor which indicated the amount of force applied. The specimens were kept under load and the reading on the digital scale indicated the force applied until the specimens fractured (Fig 5) indicating the breaking load of the material. Then the transverse strength of the materials were calculated using the following formula:

| Fig 4 : Samples Loaded In Universal Testing Machine

|

| Fig 5 : Fractured Samples After Three Point Bending Test

|

Statistical Analysis

One way Analysis of variance (ANOVA) was used in this study to find the significant difference in the transverse strength between the groups. Where F indicates, Fisher value and p indicates probability value. The Post-Hoc Tukey test was used to find the pair-wise significance of transverse strength increase between all the twenty subgroups.

Discussion

The present study was undertaken to compare the transverse strength of our heat cure denture base resins at different glass fibre concentrations. Transverse strength is a collective measurement of tensile, compressive and shear strength simultaneously[7]. Higher the value of transverse strength of heat cure denture base resin, superior will be its clinical performance.

For standardization of specimens, a stainless steel die plate of dimension 60mm in length, 10mm in width and 4mm in thickness was fabricated as per ADA specification no. 12 for denture base resins[8]. Method used to calculate transverse strength was in accordance with the previous studies done by Gulay Uzun & Nur Hersek. They made PMMA samples of the 60 x 10 x 4 mm dimensions[9]. These samples were kept in water for 2 weeks before testing. Water storage was used to determine the longevity of the obtained mechanical properties of dental materials in the demanding environment of the oral cavity. The prime and most frequent fracture of the upper denture occurs in mid line and the fracture mechanism and the influence of the masticatory load which is applied onto the dentures are very similar to the three point bending test. So the samples were tested for the transverse strength at Universal Testing Machine at a cross head speed of 0.5cm/min where each sample was placed on two supports 50 mm apart. This dimension represente the space between maxillary molars in a complete denture. A load was applied using a centrally located rod until fracture occurred.

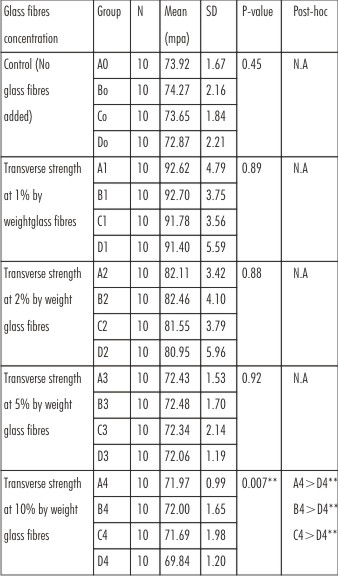

Table 3 shows the mean transverse strength of Group A to Group D samples before and after glass fibre reinforcement. It can be observed that there is increase in transverse strength after glass fibre reinforcement upto the conccentrationsof 2% where 1% weight show highest transverse strength.

| Table 3 .Comparative Evaluation Of Transverse Strength (Mpa) Of Heat Cure Denture Base Resins After Addition Of Glass Fibres

|

Table 3 also shows the between group comparison of transverse strength at 1%, 2%, 5% and 10% by weight glass fibres concentration. It is evident from this table that at concentration of 5% the transverse strength starts decreasing and at 10% concentration there is significant decrease in transverse strength which became even lower than the control group. Post Hoc Tukey HSD test for comparison between also groups shows that decrease in transverse strength in D4 subgroup is highly significant with respect to A4, B4 & C4 subgroup at 10% by weight glass fibre concentration.

When 1% concentration of glass fibres was used, improvement in transverse strength was noticed. Increase of young modulus with carbon or glass fibres incorporation was noted in the investigation by Inamura et al[10]. It is also seen that, the modulus of elasticity for the 1% treated specimens after repair was found significantly higher than the plain unreinforced specimens[11]. Silanized glass fibres also shown the significant strengthening effect this was probably due to improved adhesion between fibres and resins which enhances the resistance[12]. The microscopic investigartion should be carried out in conjuction with other studies of glass fibre reinforced resin as the interface between the fibres and matrix can play an important role in the sucess of the overall reinforcement[13]. e.g fibres that are well integrated within the matrix may not prevent crack propagation,and fibres that demonstrate poor interfacial bonding may be plucked out of the matrix or act as areas of stress concentration,weakening rather than strengthening the acrylic resin.

But as the glass fibre conentration kept on increasing, there was a drop in transverse strength because at higher concentration glass fibres tend to clump together when mixed with monomer increasing porosity. This form void spaces and act as inclusive bodies that brake the homogeneous matrix of the PMMA[4]. As the concentration of glass fibres increases, chances of porosity are increased in the PMMA samples.

According to present study, addition of glass fibre at lower conc. has shown positive effect on the transverse strength of denture base resins. However further studies are required to evaluate health hazards of glass fibre on dental personal and patients, subsequently properties other than transverse strength can also be studied.

Conclusion

This study was focused to evaluate the effect of glass fibres at different concentration on transverse strength of heat cure denture base resins. There appeared to be a specific limit of glass fibre concentration above which, the level of enhancement in transverse strength was reduced. High concentration of glass fibres actually reversed the effect and weakened the resin. These findings display a favourable combination of properties that might be of clinical importance. On the basis of the results of the present study, following conclusion can be drawn. 1) Reinforcing heat cure denture base resins with glass fibres mixed in random form proved to be a useful and simple laboratory technique to strengthen heat cure denture base resins. 2) However it was observed that low concentration of glass fibre (1% & 2% by weight) increased the transverse strength of heat cure denture base resins. High concentration of glass fibre 10% by weight decreased the transverse strength of heat cure denture base resins.

References

1. Jacob John, Ganagadha SA, and Ila S. Flexural strength of heat polymerized polymethyl methacrylate denture resin reinforcement with glass, aramid or nylon fiber. J Prosthet Dent 2001; 86: 424 –7.

2. Kelly E. Fatigue failure in denture base polymers. J Prosthet Dent 1969; 21: 257-66.

3. PolyzoisGL, Trantili PA, Fragou MJ and Andreopoulo. Fracture force, deflection at fracture and toughness of repaired denture resin subjected to microwave polymerization or reinforced with wire or glass fiber. J Prosthet Dent 2001;86; 613-619

4. Stipho HD. Effect of glass fibre reinforcement on some mechanical properties of autopolymerizing polymethyl methacrylate .J Prosthet Dent 1998; 79:580-4.

5. Vojvodic D, Komar D and Schauperl Z. Influence of different glass fibre reinforcement on denture base polymer strength. medicinski glasnic 2009;6(2):227-234

6. Ertas N, Hersek N and Sahin E. Water sorption and dimensional changes of denture base polymer reinforced with glass fibers in continuous unidirectional and woven form. Int J Prosthodont 2000; 13: 487-93.

7. Anusavice KJ. Phillips science of dental materials. 11th ed. St louis, MO: Saunders;2003: page.737

8. American Dental Association Specification Number 12 for denture base polymers.4th revision, approved Dec 1973, effective Jan 1st 1976.

9. Uzun G, Hersek N and Tincer T. Effect of woven fibre reinforcement on the impact and transverse strength of a denture base resin. J Prosthet Dent 1999; 81: 616-20

10. Iumara M, Nagato H, Aita E, et al. Self- cure dental acrylate resin reinforced with glass fibres – part 1: bending and tensile test. Jpn J Pedodont 1988;26:328-35

11. Stipho HD. Repair of acrylic resin denture base reinforced with glass fibre. J Prosthet Dent 1998; 80:546-50.

12. Vallittu PK and Lassila VP. Reinforcement of acrylic resin denture base material with metal or fiber strengtheners. J Oral Rehabilitation 1992; 225-30.

13. Jagger DC, Harrison A and Jandt KD. An investigation of self reinforced polymethylmethacrylate denture base acrylic resin using scanning electron and Atomic force microscopy. Int J Prosthodont 2000; 13: 526-31.

|